The Hoverseen automatic drone system for Parrot ANAFI Thermal is operated at Armor Group on the outskirts of Nantes (France). With a flight authorization without a remote pilot, it is used daily for surveillance and preventive inspection of the explosive atmosphere classified site at La Chevrolière.

Hoverseen automatic drone system for Parrot ANAFI Thermal use cases at ARMOR Group

Partnerships

29/06/2022

The site of La Chevrolière, explosive atmosphere classified

Armor is a world's No. 1 industrial group in thermal transfer technology.

Its La Chevrolière site is dedicated to the manufacture of inked rollers for barcode printing and flexible photovoltaic films. With an area of 9 hectares for a workforce of 350 people on site, it combines a double explosive risk (ATEX) and environmental risk (ICPE).

The company wanted to benefit from an automatic drone system to strengthen safety and security, and to further reduce the level of human, material, and environmental risks inherent in its activity. More specifically, it had formulated 3 main objectives: optimize the surveillance of the premises, strengthen the safety of people, and reduce the risk of fire. Installing an automatic drone system should also promote the responsiveness of security guards and their ability to anticipate.

Conventionally equipped with a network of surveillance cameras, a Milestone video management solution and a team of on-site security guards, some parts of the site remained less well covered and the inspection of hard-to-reach areas was limited to a few annual interventions.

On-premises deployment process

The first visit made it possible to study the site, and Armor’s human and technological safety installation.

In order to reach the areas designated to be monitored Hoverseen has defined the shortest and safest paths in terms of human security and network accessibility. The privacy zones of the neighborhood have also been specified in the flight plan.

On this basis, the application for authorization to fly without a remote pilot has been prepared and sent to the French Civil Aviation Authority (DGAC). It was obtained for day and night flights, even though the site is in suburban area, at 5km from Nantes airport.

The installation of the automatic drone on site took place in parallel with the request for flight authorization:

- As the Hoverseen system is compatible with video management solutions (VMS), connecting to Milestone has been as easy as adding a new IP camera. Note that it is not connected to the Internet but only to the private and secure Armor network.

- The agents have been trained in the handling of the Hoverseen system, according to programs also validated by the DGAC: 1 day for the security guards and 1.5 day for their supervisor.

- A committee on “health, safety and working conditions” (CHSCT) has been held beforehand. The overall package was presented to the employees and well received. The drone, around 500g, has not been perceived as a worrying object.

Use and benefit of the Hoverseen solution

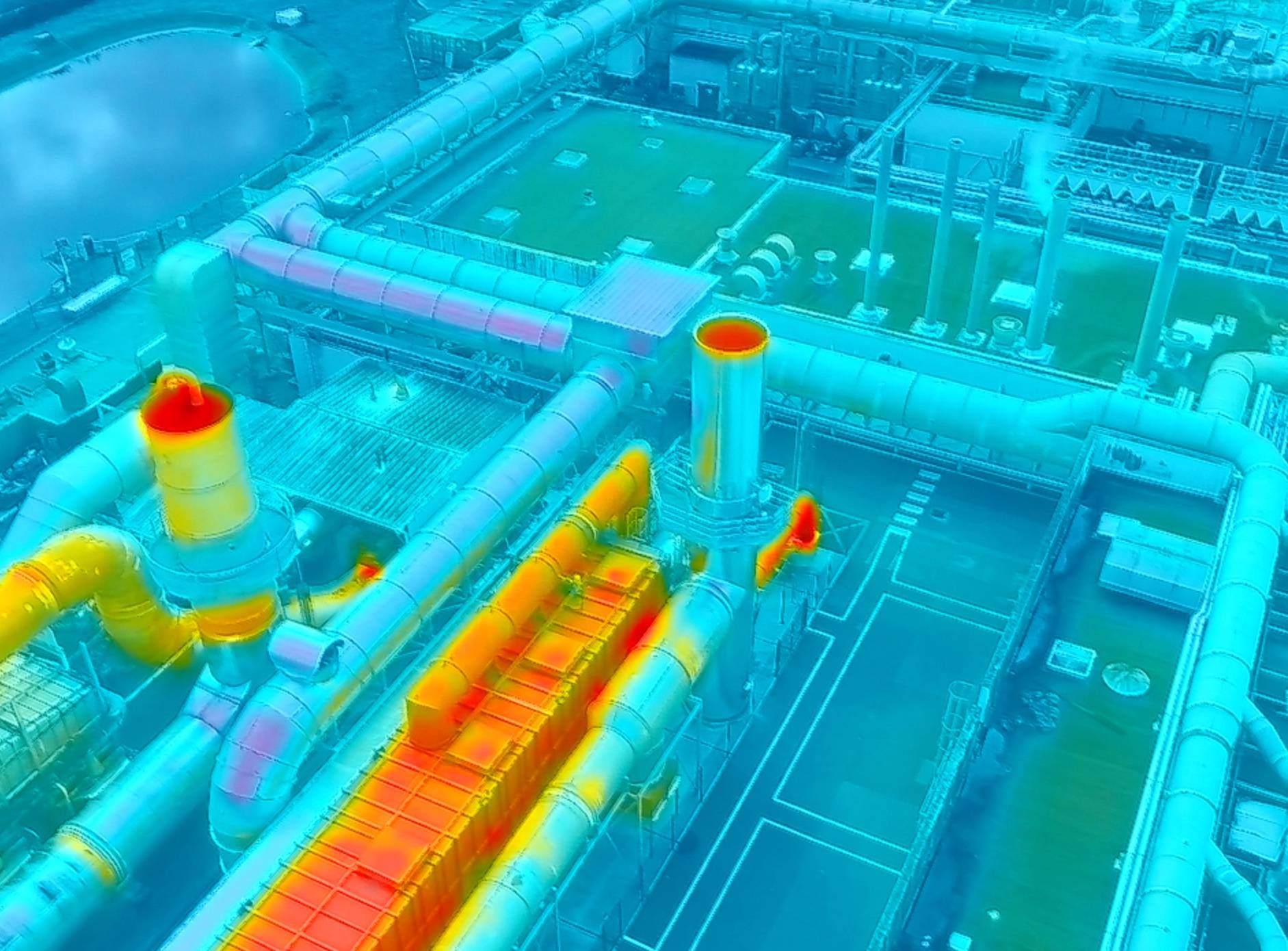

Today, the La Chevrolière site carries out several automatic flights a day, without a remote pilot, and under the supervision of security guards. They launch the flights and observe in real time the video feedback on the security screens. In a few minutes they have a complete aerial view of the terrain. They can visualize areas that are not easily accessible or difficult to monitor such as the buildings’ roof or the delivery docks.

Their movements on site are thus more limited, and the associated risk is reduced, in particular in the event of an intrusion.

In an Industry 4.0 approach, Armor wanted the solution to carry out by the way a preventive inspection of the infrastructures. To do so, the drone is configured to catch for example an unusual temperature difference or an abnormal situation in an area that is difficult to access. Being able to identify risk situations well in advance of an incident makes it possible to quickly determine the right actions to implement. In addition to real-time vision by the guards, high-definition aerial images are also retained and available after flights. They can be consulted to analyze the evolution of the site over time.